H. R. C Fuse

H. R. C Fuse image

Get Latest Price Request a quote

Quick Details

Product Details

kV to 38 kV grounded systems with 100 or 200 A nominal currents.

Especially designed to protect transformers, capacitors, cables or lines.

It is robust construction, made of rigorously tested material, will interrupt all faults under the

most severe conditions, maintaining mechanical and electric characteristics.

The inserts, hardware and structural bolts and nuts are made from heavy galvanized steel.

The Fuse Cutout type OEI can be applied on all three-phase system rated at or below the maximum

operational rating of the cutout.

IEC61109, BS 3288-2

| 4 | Connector name | Aluminum compression connector Type H, 1/0 AL 1/0 ACSR. |

|

| 5 | Raw material | The connectors must be made of alloy pressure-cast aluminum, with a high degree of Rockwell RH30 hardness, or a 1100-0 high conductivity aluminum ductile alloy, which is a highly pure aluminum |

|

| 6 | Rules | ANSI C119.4 | |

| 7 | Quality certificate | ISO-9001 or recent | |

| 8 | Finish | The surface of the connectors should be smooth , free of astilaldura or imperfections |

|

| 9 | Shape | H | |

| 10 | Main Calibres Range | ACSR | 1/0 |

| 11 | Secondary Calibers Range | ACSR | 1/0 |

| 12 | High | inch | 1.42 (36) |

| 13 | Long | inch | 1.88 (47.75) |

| 14 | Width | inch | 0.89 (22.50) |

| 15 | External Comma | The external part of the connector should be placed with a bath of metallic stamp, in order to prevent environmental corrosion to moisture and air on the contact surface |

|

| 16 | Inhibitory compound | Each connector must present in the slot a Composite of the oxide and galvanic corrosion |

|

| 17 | Identification mark | Each connector should be marked with the manufacturer’s symbol, catalog number, Application driver range, number of die to occupy. When this information is not possible to present in the body of the connector, it will be printed on the connector bag except for the manufacturer’s brand and name, which must necessarily be indicated on the body of the connector |

|

| 18 | Packaging | Each connector should be individually packed in a high plastic bag resistance duly sealed for intempere, in order to prevent external agents from damaging it and causing premature oxidation. |

| S/N |

Detail |

Unit |

Data |

| 1. | Description |

33kV silicon composite pin insulator for mounting on steel cross arms as per drawing ZAM-GEN-87-E-12904 below |

|

| 2. | Type |

Silicon composite pin insulators complete with spindle, washer, nut and lock nut |

|

| 3. | Rated voltage |

kV |

33 |

| 4. | Highest system voltge |

kV |

36 |

HIGH VOLTAGE EXPULSION TYPE FUSE LINKS

TABLE OF CONTENTS

ITEM TITLE PAGE

PART 1 GENERAL

1.01 SCOPE E13 1

1.02 STANDARDS E13 1

1.03 SERVICE CONDITIONS E13 2

1.04 SYSTEM CONDITIONS E13 2

1.05 TESTING E13 2

1.06 SPARES E13 3

1.07 PACKING AND SHIPMENT E13 3

1.08 SUBMITTALS E13 3

PART 2 PRODUCTS

2.01 DESIGN E13 4

A. Standardization of Fuse Links E13 4

B. Rating of Fuse Links E13 4

C. Characteristics of Fuse Links E13 4

2.02 MATERIALS E13 4

A. Current Carrying Parts of Fuse Links E13 4

B. Fuse Link Button E13 5

C. Length of Fuse Links E13 5

D. Pull on Fuse Links E13 5

E. Identification E13 5

TECHNICAL DATA SCHEDULE E13 6

PART 1 GENERAL

1.01 SCOPE

This Specification covers the design, manufacturing, testing, supply, delivery and performance requirements of HV Expulsion Type Fuse Links for use by the Electricity Company of Ghana Limited.

1.02 STANDARDS

The fuse links shall comply with the latest editions of and amendments to, the standards/specifications listed below:

IEC – International Electrotechnical Commission

IEC 60282 – High Voltage Fuses Part 2: Expulsion and similar fuses

ANSI American National Standards Institute

IEEE C37.41 – Design for High Voltage Fuses, Distribution Enclosed Single Pole Air Switches. Fuse Disconnecting Switches and Accessories.

ANSI C37.42 – American National Standard Specifications for Distribution Cutouts and Fuse Links.

NEMA National Electrical Manufacturers Association

NEMA SG2 – High Voltage Fuses

1.03 SERVICE CONDITIONS

As in Specification H0C

1.04 SYSTEM CONDITIONS

As in Specification H0C

1.05 TESTING

Type Tests

A. The Supplier shall confirm on the attached schedule that the following tests have been performed according to ANSI C37.42.

1. Melting Current Tests; Table 6

2. Temperature Rise Tests

3. Time/Current Characteristic Tests

B. Type/Design Tests may (at the Purchaser’s discretion) be dispensed with if the Supplier/Contractor furnishes evidence to the Purchaser’s satisfaction that the relevant tests have already been performed on identical equipment. In this case the Supplier shall provide documentary proof in the form of Certified Test Certificates that the assembled equipment and its component parts been successfully typetested by an independent testing authority in accordance with the relevant clauses of referenced Standards. Test Certificates as evidence of successful completion of type tests shall be submitted as part of the Bid.

C. Inspection

The Purchaser reserves the right to witness the manufacturing process, any type tests specifically performed on the materials to be supplied to Customer and any routine tests required in the manufacture and supply of such equipment. The Supplier shall provide free access to the Purchaser to any site where such manufacturing process, or tests, either type or routine tests are taking place. The Supplier shall bear the in plant costs of such witness. The Supplier shall provide the Purchaser of a schedule of manufacture and tests at least two weeks before the events are to occur.

1.06 SPARES

(NOT APPLICABLE)

1.07 PACKING AND SHIPMENT

As in Specification H0C

1.08 SUBMITTALS

As in Specification H0C

PART 2 PRODUCTS

2.01 DESIGN

A. Standardization of Fuse Links (Mechanical/Interchangeable).

High voltage expulsion fuses shall be suitable for use on the Expulsion fusegears described in the associated specifications H16 and H34.

B. Rating of Fuse Links

The preferred rating of fuse links shall be 3A, 5A, 8A, 16A, 25A, 40A, 63A and 100A at 11kV and 1A, 2A, 3A, 5A, 8A, 16A, 20A and 31.5A at 33kV. The rated current of the fuse link is the maximum current which it will carry continuously without deterioration and undue heating. Supplier shall state on the attached schedule the maximum temperature in oC attained by the fuse link after continuous operation at maximum rating.

C. Performance Characteristics of Fuse Links

1. The fuse links are required to give protection against short circuits. They shall be so rated and shall have such blowing characteristics as to be suitable for selective operations with the fuse links at present in use on the system namely Type K i.e. fast, fuse links to NEMA SG2 and ANSI C37.42 1981.

2. The Supplier shall present to the Purchaser timecurrent characteristics of all the distribution fuselinks on offer. The performance characteristics of the fuselinks shall include:

(a) Meltingtimecurrent characteristics

(b) Total clearingtimecurrent

The timecurrent characteristics shall be presented as curves.

The Supplier shall state the minimum and maximum melting currents required to melt the fuse links at the three appropriate time points used in Table 6 {meltingcurrents for TypeK (fast) fuse links) of ANSI C37.42 1981

2.02 MATERIALS

A. Current carrying Parts of Fuse Links

All current carrying parts of the fuse links shall be nonferrous material; the main requirements being resistance to atmospheric corrosion. Tin is not acceptable as a possible element.

Supplier shall state composition of:

1. Fuse Element

2. Fuse Link

B. Fuse Link Button

The diameter of the button head cap on fuse links shall be 19.1mm. Removable type button heads are preferred for use with 11kV fusegear.

C. Length of Fuse Links

The minimum overall length of fuse links rated 1 to 100 amperes shall be:

: 510mm for 11kV units per ANSI C.37.42

: 762mm for 33kV units per ANSI C.37.42

D. Pull on Fuse Links (Tensile Withstand Strength)

The expulsion fusegear shall operate satisfactorily while exerting a pull of 44.5N on the fuse link per ANSI C.37.42, 3.2.3.4 1981.

E. Identification

Each fuse link must have stamped on it:

1. Manufacturers name or identifying mark

2. Continuous current rating

3. Type designation, K or T

SPECIFICATION H13

HIGH VOLTAGE EXPULSION TYPE FUSE LINKS

TECHNICAL DATA SCHEDULE

Item Description Unit Purchaser’s Supplier’s

Requirements Offer

1. Standard specification with which See Clause

fuse link shall comply and be tested. 1.02 __________

2. Are Type test certificates according

to Clause 1.05? Yes __________

3. Are type test certificates, quality

control procedures, and users

list included with tender? Yes __________

4. Can fuse links be used in any make

of IEC standard Fusegear? Yes __________

5. Rated current of fuse 3, 5, 8, 16, 25, 40

links 63 and 100 at 11kV,

1, 2, 3, 5, 8, 16 __________

20, 31.5A at 33kV. __________

6. Maximum Temperature in oC

attained by the Fuse Link after

continuous operation at maximum

rating with maximum ambient

temperature of 40oC. oC __________

7. Type of Fuse links? __________

Fusing current tolerance Melting

current (300, 10, 0.1, sec) sec __________

8. Composition of

1. Fuse element (Tin not acceptable) __________

2. fuse link __________

9. Diameter of fuse link

button and type mm 19.1 __________

10. Length of fuse links for:

11kV isolators mm 510 __________

33kV isolators mm 762 __________

11. Tensile withstand strength of

fuse links N 44.5 __________

12. Are fuse links stamped

according to Clause 2.02 E? Yes __________

SIGNED: __________________________________

COMPANY: _________________________________

POSITION IN COMPANY: _________________________________

Date: _____________________ _______________________

COMPANY STAMP

We are China H. R. C Fuse manufacture and supplier,You can get more details with Email,you will get cheap price or factory price.

Get Latest Price Request a quote

Popular Fuse Link Products

High Temperature-Resistant Gloves (aluminium foil)

Driving Gloves Made of Cow Hide Leather

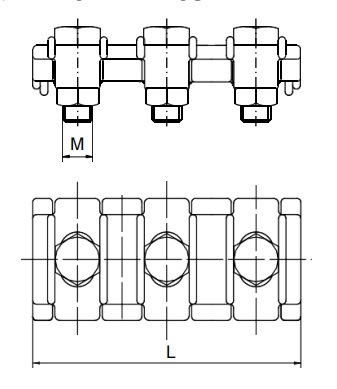

Spacers for Two-Bundle Conductor Type Mrj

Popular H. R. C. Fuses Products

Popular High Voltage Fuse Products

2 Threads Latex Glovespolyester Linerorange7-11

Cut Resistance Gloves, Grade 2hppe + Dyneemagrey7-11

Popular jgtrade1 Products

ED-2c, S80 Medium Voltage Porcelain Electric Shackle Insulator

Switch Disconnector Fuse Holder, 27 Kv - 100 AMP, Without Arc Chute

Fuse Cutout, Drop out Fuses 12kv 100A

Polymer High-Voltge Expulsion Type Fuses

Polymer Fuse Cutout, Drop out Fuses 12 Kv 100A

Tags: Fuse Link, H. R. C. Fuses, High Voltage Fuse, jgtrade1