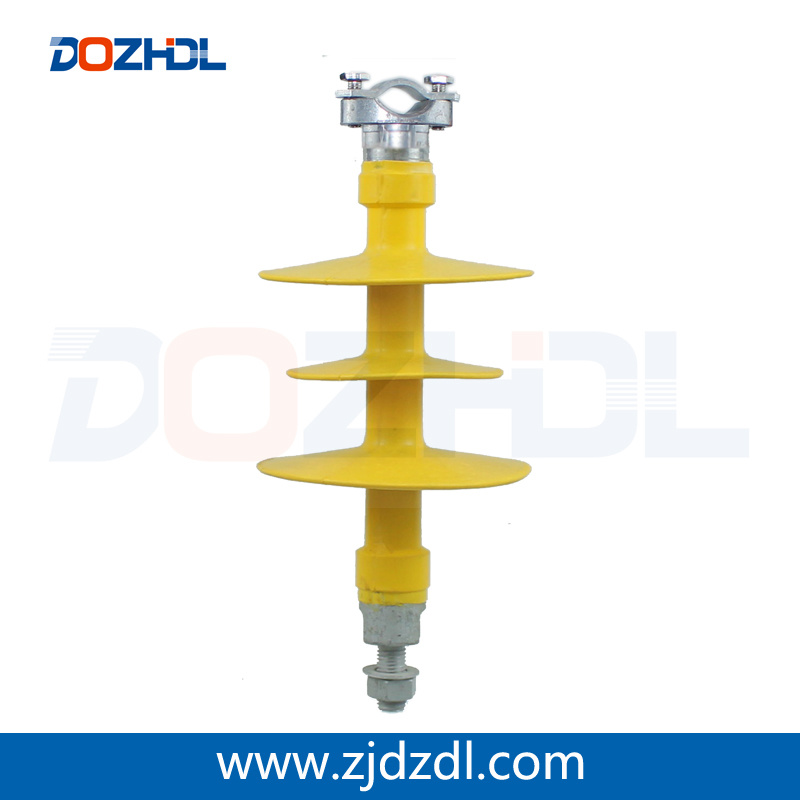

Shackle Insulator

Shackle Insulator image

Get Latest Price Request a quote

Quick Details

Product Details

The Composite Insulators comply with the latest editions of and amendments to, the standards/specification listed below:

CSA CANADIAN STANDARDS ASSOCIATION

G164-4 – Hot dip galvanizing of Irregular Shaped Articles

CAN/CSA – Quality Assurance Program Categories 2299.3

ANSI – AMERICAN NATIONAL STANDARDS INSTITUTE

C29.1 – American Standard Test Method For Electrical Power Insulators

C29.7 – American Standard For Wet-processed Porcelain Insulators (High Voltage Line Post Type) Electrical Power Insulators

987-1985 – IEEE Guide For Application of Composite Insulators

D750 – Recommended Practice for Operating Light and Weather Exposure Apparatus (Carbon Arc Type) For Artificial Weather Testing Of Rubber Compounds.

D1499 – Recommended Practice For Exposure of Plastics.

D2240 – Rubber Properties, Durometer Hardness

D2565 – Recommended Practice For Operating Xenon-Arc Light And Water Exposure Apparatus Plastics.

The weathershed of the Post Insulators shall be manufactured from either Hydrated Alumina Ethylene Propylene Copolymer (EPM) as the primary constituent or Silicone Elastomers. The weathershead shall be injection moulded and brought to final cure state in one continuous process to prevent internal undercure or surface overcure. Additionally, the weathershead shall provide hydrophobic surface, even after exposure to tropical marine environment, ultra violent rays and moisture.

Core

The rod or the core is manufactured from Fibreglass, having 70-75 by weight of auxiliary aligned glass fibre bonded by an organic resin. The rod is either be cast or pultruded.

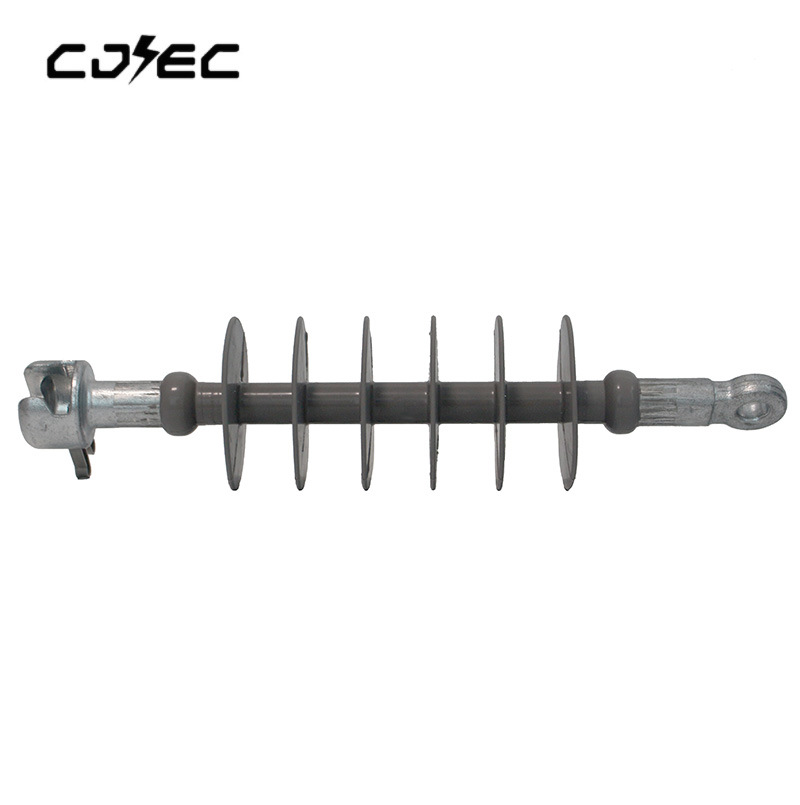

The end fittings are have the following properties:

i. are compressed onto the Fibreglass rod member

ii. are not move relative to the central Fibreglass rod at applied loads equal to two times the rated Routine Test Load or maximum designed cantilever loads

iii. are attracted to the rod after completion of all external heat processes used to cure or bond component parts.

The insulator are provided load limiting bases that will deform under longitudinal loading of more than 100% of the rated design cantilever load.

Performance Characteristics

The Polymeric Insulators are meet the under listed performance characteristics.

| ITEM |

11kV |

33KV |

| Dry Flashover Withstand |

90kV |

180kV |

| Wet flashover withstand |

70kV |

165kV |

| Positive Impulse Critical flashover |

145kV |

300kV |

| Maximum Radio Interference Voltage |

Below 1micro volt |

Below 1 micro volt |

| Design Tension Strength |

100kN |

100kN |

| Residual Strength after Power Arc |

80kN |

80kN |

| Mechanical Proof Test Load |

45kN |

45kN |

| Maximum Sustained Load |

34kN |

34kN |

| Design Torque Rating |

83 Nm |

83 Nm |

The insulator are suitable for accepting both aluminium and copper conductors having cross-sectional areas ranging from 35mm2 to 265mm2. The insulators are designed for mounting on the angle and channel crossarms specified in Specification E14

All exposed ferrous part shall be treated against corrosion. Treatment by hot dip galvanizing is preferable.

We are China Shackle Insulator manufacture and supplier,You can get more details with Email,you will get cheap price or factory price.

Get Latest Price Request a quote

Popular Composite Insulator Products

Composite Suspension Insulator for Transmission Lines

Fpq-10/5 Pin Type Composite Insulator/ Silicone Rubber Insulator

Silicon Rubber Glass Composite Insulator

33kv High Voltage Composite Post Insulator / Electrical Polymer Insulator

Popular jgtrade1 Products

Popular Polymer Insulator Products

Polymer Insulator for High Voltage Overhead Transmission Line

Overheadlinefittings-Anchoringclampforfiberopticalcable

Composite Polymer Insulator/Post Silicone Rubber Insulator (10kv-35kv)

24kv Cantilever Composite Insulator Catenary Type

100kv AC and DC High Voltage Withstand Voltage Tester

Silicon Rubber Pin Type Insulator for Transmission and Distribution

Popular Silicone Rubber Insulator Products

ANSI 54-2 for Retained 4-1 / 4 "X 2-7 / 8"

LV Shackle Insulator - Porcelain

Isoladores De Porcelana P-33y Polymer Insulator 10kn

Technical Data of LV. ABC (Aerial Bundle Cable) Fittings by Sehco

Tags: Composite Insulator, jgtrade1, Polymer Insulator, Silicone Rubber Insulator