Insulation Piercing Clamp 25-75sqmm

Insulation Piercing Clamp 25-75sqmm image

Get Latest Price Request a quote

Quick Details

Product Details

Insulation Piercing Connectors (IPC) is used for taking Tee/Tap-off/Service connectors to an ABC/Bare Overhead Line.

The insulation piercing connectors should conform to the standard NF C 33-020 or equivalent standard, if any.

Insulation Piercing Connectors are designed to make a connection between the uncut main conductor and a branch cable conductor without having to strip either cable to expose the conductor. Instead, the tightening action of the IPC will first pierce the insulation, then make good electrical contact between the main end and branch conductor while simultaneously insulating and sealing the connection.

3.5.1. Constructional Features of IPC

The housing shall be made entirely of mechanical and weather resistant plastic insulation material and no metallic part outside the housing is acceptable except for the tightening bolt.

Any metallic part that is exposed must not be capable of carrying a potential during or after connector installation.

Screws or nuts assigned for fitting with IPC (Insulation Piercing connector), must be fitted with Torque limiting shear heads to prevent over tightening or under tightening (min & max torque values to be specified by Manufacturer).

The IPC must perform piercing and connection on Main and Branch cable simultaneously. The IPCs shall be water proof and the water tightness shall be ensured by appropriate elastomer materials and not by grease or paste alone. Design of IPC should be such as to not cause damage to the insulation of adjacent conductors due to vibration and relative movement during service.

The connector shall have a rigid removable end cap which can be slide fitted on the main connector body on either right or left by the installer(depending on site requirement) for sealing the cut end of the branch cable. Once the connector is fitted, it should not be possible to remove the cap without removing the connector.

3.5.2. Inspection and Testing

Tests shall be according to EN 50483 or equivalent.

3.1 Strain clamp

3.18.1 Design

Bolted dead-end strain clamps, clevis type, minimum breaking load 70kN, all ferrous parts to be hot-dip galvanized. Suitable for conductor diameter 5 – 14mm complying with the following standards.

DIN 48215 Clamps and connectors for overhead power line

IEC 60228 Conductors of insulated cables

BS 6360 Specification for conductors in insulated cables

BS 03288 Insulator and conductor fittings for overhead power lines

3.18.2. Material

The parts of the clamps shall be manufactured from materials, which withstand the mechanical loads and environmental circumstances. All ferrous parts shall be hot-dip galvanized.

Each clamp shall be marked with the name or trademark of the manufacturer. The markings shall be legible and durable.

3.18.3. Testing

Type and sample tests shall be as per the relevant standard including;

Verification of dimensions

Mechanical test

Electrical test

Galvanizing test

3.1 Stay rod for MV

3.17.1 Standard

Any Standard which fits our design requirements is acceptable.

3.17.2. Material

* To protect corrosion stay rod shall be well hot dip-galvanized.

3.17.3 Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Each and every dimension according to the given drawing.

3.17.4 Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection.

c. Galvanizing test

Stay rod for LV

3.16.1 Standard

Any Standard which fits our design requirements is acceptable.

3.16.2. Material

* To protect corrosion stay rod shall be well hot dip-galvanized.

3.16.3. Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Each and every dimension according to the given drawing.

3.16.4 Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection.

c. Galvanizing test

3.1 Stay plate for MV

3.15.1 Standard

Any Standard which fits our design requirements is acceptable.

3.15.2. Material

* To protect corrosion stay plate shall be well hot dip-galvanized.

3.15.3. Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Each and every dimension according to the given drawing.

3.15.4 Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection.

c. Galvanizing test

3.1 Stay plate for LV

3.14.1 Standard

Any Standard which fits our design requirements is acceptable.

3.14.2. Material

* To protect corrosion stay plate shall be well hot dip-galvanized.

3.14.3 Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Each and every dimension according to the given drawing.

3.14.4 Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection.

c. Galvanizing test

M16, 400mm long bolt nut and washer

3.12.1. Standard

BS 4190 or equivalent is acceptable.

3.12.2. Design

Long bolt nominal diameter (d) 16 mm and lead 2.

Minor threaded diameter (dk) 14mm.

Thickness of head (k) as per BS standard

The nut shall fit long bolt threaded diameter.

Thickness of nut head (m) as per BS standard

Width of head across flats (s) as per BS standard.

Width of head across angle (e) as per BS standard

Washer diameter (d1) as per BS standard.

Thickness of washer as per BS standard.

Inside diameter of washer (h) as per BS standard

To protect corrosion long bolt shall be well hot dip-galvanized.

3.12.3. Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Threads of long bolt shall be according to the design dimension.

* Each and every dimension according to the given drawing.

3.12.4 Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection

c. Galvanizing test

3.1 M16, 300mm long bolt nut and washer

3.11.1 Standard

BS 4190 or equivalent is acceptable.

3.11.2 Design

Long bolt nominal diameter (d) 16 mm and lead 2.

Minor threaded diameter (dk) 14mm.

Thickness of head (k) as per BS standard

The nut shall fit long bolt threaded diameter.

Thickness of nut head (m) as per BS standard

Width of head across flats (s) as per BS standard.

Width of head across angle (e) as per BS standard

Washer diameter (d1) as per BS standard.

Thickness of washer as per BS standard.

Inside diameter of washer (h) as per BS standard

To protect corrosion long bolt shall be well hot dip-galvanized.

3.11.3. Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Threads of long bolt shall be according to the design dimension.

* Each and every dimension according to the given drawing.

3.11.4 Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection

c. Galvanizing test

3.1 Earthing Rod with Clamp

Profiled earthing rods of hot dip galvanized steel with connecting lugs. Cross-section and length of profile shall be 50x50x3 mm and 3 m long, respectively. The earthing rod should also be in accordance with the corresponding drawing of this tender.

Earthing rod clamps suitable for stranded copper conductor of 25-35 mm2.

3.10.1 Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Each and every dimension according to the given drawing.

3.10.2. Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection

c. Galvanizing test

Standard :BS or equivalent is acceptable.

Design

– Small collar nominal diameter (d) 12 mm and lead 2.

– Minor threaded diameter (dk) 10mm.

– Thickness of head (k) as per BS standard

– The nut shall fit small collar threaded diameter.

– Thickness of nut head (m) as per BS standard

– Width of head across flats (s) as per BS standard.

– Width of head across angle (e) as per BS standard

– Washer diameter (d1) as per BS standard.

– Thickness of washer as per BS standard.

– Inside diameter of washer (h) as per BS standard

To protect corrosion small collar shall be well hot dip-galvanized.

3.13.3 Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Threads of small collar shall be according to the design dimension.

* Each and every dimension according to the given drawing.

3.13.4. Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection

c. Galvanizing test

Big collar, type 2

Standard

BS or equivalent is acceptable.

Design

– Big collar nominal diameter (d) 16 mm and lead 2.

– Minor threaded diameter (dk) 14mm.

– Thickness of head (k) as per BS standard

– The nut shall fit big collar threaded diameter.

– Thickness of nut head (m) as per BS standard

– Width of head across flats (s) as per BS standard.

– Width of head across angle (e) as per BS standard

– Washer diameter (d1) as per BS standard.

– Thickness of washer as per BS standard.

– Inside diameter of washer (h) as per BS standard

To protect corrosion big collar shall be well hot dip-galvanized.

. Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

* Threads of big collar shall be according to the design dimension.

* Each and every dimension according to the given drawing.

Testing

The following testing shall be carried out.

a. Visual inspection

b. Size inspection

c. Galvanizing test

Tie Strap

The strap shall have a cross section dimension of 50 x 5 mm

The strap shall have a cross section dimension of 50 x 5 mm.

The strap manufactured for suspension/intermediate assembly according to the given drawing (see the drawing)

Yield strength of tie strap must be 240N/mm2.

To protect tie strap from corrosion it shall be hot dip-galvanized.

Guaranteed Value

The following values are guaranteed by the manufacturers as stipulated by the guaranteed characteristics table

§ Each and every dimension

§ Material strength.

3.7.4. Testing

The following testing must be carried out.

a. Visual inspection

b. Size and dimension verification.

U channel cross-arm for 33kV

Any standard equivalent to GB/T 707 1988, 80×43, 5/8 and 100×48, 5.3/8.5 is accepted.

For suspension, T-off, angle and dead end assembly shall have a cross section dimension of

80 x 43 x 5/8mm

For transformer base U-cross arms shall have a dimension of 100x48x5.3/8.5

U-cross arms manufactured for suspension, T-off, angle, dead end and transformer base

assembly as per the drawing

To protect U-cross arms against corrosion U-cross arms shall be hot dip-galvanized

Yield strength of U-cross arm 240N/mm2

Test for yield stress

Percentage elongation test

Bend test

Chemical composition test

Galvanization tests thickness of Zn coating

Weight of Zn Coating

Uniformity of Zn coating

Adhesion test of Zn coating

Visual inspection

Weight verification

Dead end hook 382

Hook threaded nominal diameter (A) 16mm

Minor threaded diameter (W) 14

Thickness of nut (M), washer diameter and thickness as per BS standard

Yield strength of pin must be 240N/mm2

LV Hook from corrosion it shall be hot dip-galvanized

Visual inspection

Size inspection

Galvanizing test

Strength test

Suspension hook M16-380

Hook threaded nominal diameter (A) 16mm

Minor threaded diameter (W) 14

Thickness of nut (M), washer diameter and thickness as per BS standard

Yield strength of pin must be 240N/mm2

To protect LV Hook from corrosion it shall be hot dip-galvanized

Testing

Visual inspection

Size inspection

Galvanizing test

Strength test

The following testing shall be carried out

Dead End Clamp ,Anchoring Clamp

The clamps should be designed to Anchor LV AB cable with insulated messenger. The clamp

should anchor/hold the neutral messenger without damaging the insulation.

The clamp should conform to the standard NFC 33041 and 33042 or equivalent. The clamp

body should be made of corrosion resistant Aluminium alloy, bail should be of stainless steel

and self adjusting wedges should be weather and UV resistant polymer.

Anchoring assemblies are used to firmly attach the messenger of ABC to a support and

transmit the mechanical tension at the end of a run or to the supporting structures at a major

change in direction.

The suspension clamp shall be manufactured from weather and UV light resistant reinforced

nylon and aluminum alloy. The clamp should provide an additional insulation between the

cable and the pole.

Clamps should be fixed with pole by eyehook/bracket. Breaking load should not be less than

15kN

Suspension Assembly is used for supporting an ABC by installation on the messenger at an

intermediate point of support such as a pole. It can accommodate small angles of deviation up

to 30o. The clamp should hold insulated messenger of diameter range from 6mm up to 12 mm.

Visual examination

Dimensional and material verification

Tensile strength

Dielectric voltage test

Climatic & corrosion ageing

Endurance test under mechanical and thermal stresses

Electrical ageing

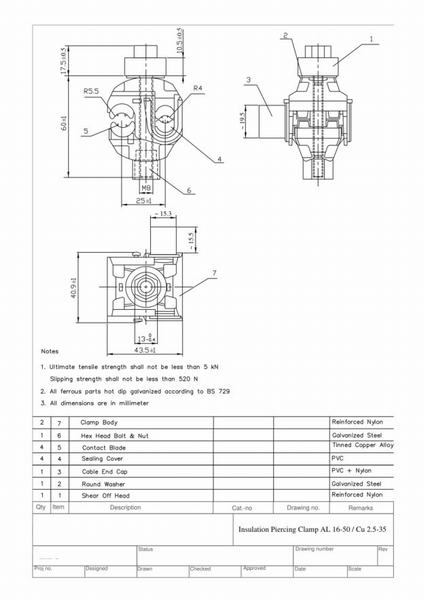

TYPE:APG-C4

NAME:Parallel groove clamp APG-C4

Specification

| Material |

||

| Material standard |

||

| Range of conductor cross-section |

16…50/2.5…35 |

|

| Range of conductor diameter, Al/Cu |

mm2 |

|

| Tensile strength |

KN | 5 |

| Thickness of zinc coating, |

mm |

43 |

| Test voltage at 50Hz for one minute in water |

kV |

6 |

Al 35-300mm² Size 105*65mm Tri-bolts Bolt M10*60 Weight 560g

We are China Insulation Piercing Clamp 25-75sqmm manufacture and supplier,You can get more details with Email,you will get cheap price or factory price.

Get Latest Price Request a quote

Popular Anchoring Clamp Products

Full Tension Aerial Cable Clamp (DR1500) 35-70mm2

Suspension Clamp for Over Head Power Line Jmasc120 /4

Suspension Clamps ADSS Fastener Column Bracket Hook Eyelet Wedge Dead End Insulation

Aerial Electrical Fittings Auminium Alloy Anchoring Clamp

Tension Clamps (ODWAC-15/ODWAC-22)

Popular Insulation Piercing Clamp Products

Insulation Piercing Connector/Wire Connector (Jma Series) (120-240, 16-120, JMA6)

Jjc Type Insulation Piercing Connectors (IPC) with 2 Bolts

Insulation Piercing Wire Connectors Jjc-50/35

Two Bolt Insulation Piercing Connector Jjc-240/240 Clamp

Aerial Bundled Cable Electrical Cable Insulation Piercing Clamp

Low Voltage Insulation Piercing Connector Piercing Clamp (IPC)

Popular jgtrade1 Products

1kv Four Core Piercing Connector (Cable Sockets)

Dead End Clamp for Self Supporting LV. ABC

Popular Stay Rod Products

Hot-DIP Galvanized Tubular Anchor Stay Rod

3/4′ ′ *8FT Guy Fittings Line Hardware Stay Assembly Set Stay Rod

Pole Line Hardware Galvanized Stay Rod M20

Terminal Straps, Adjustable Plates 2holes, 3holes, and 4holes

Vic Pole Line Hardware Fittings Oval Eye Bolt

Tags: Anchoring Clamp, Insulation Piercing Clamp, jgtrade1, Stay Rod